Engineering Black Book Pdf

The Simpsons' Creators Axe Classic 'Stark Raving Dad' Episode Featuring Michael Jackson - R.  Kelly Stan Confronts Singers Publicist During Press Conference: 'What The Fuck You Talkin' Bout, Fam' - Ruff Rydin: DMX & Swizz Beatz Back In The Studio - R.

Kelly Stan Confronts Singers Publicist During Press Conference: 'What The Fuck You Talkin' Bout, Fam' - Ruff Rydin: DMX & Swizz Beatz Back In The Studio - R.

Engineers Black Book (Data Sheets, Formulae, Reference Tables, Equivalent Charts) [Pat Rapp] on Amazon.com. *FREE* shipping on qualifying offers. How can I purchase an Engineer's Black Book? I know a lot of people who're interested in either an app for their phones, or PDF/Kindle compatible version.

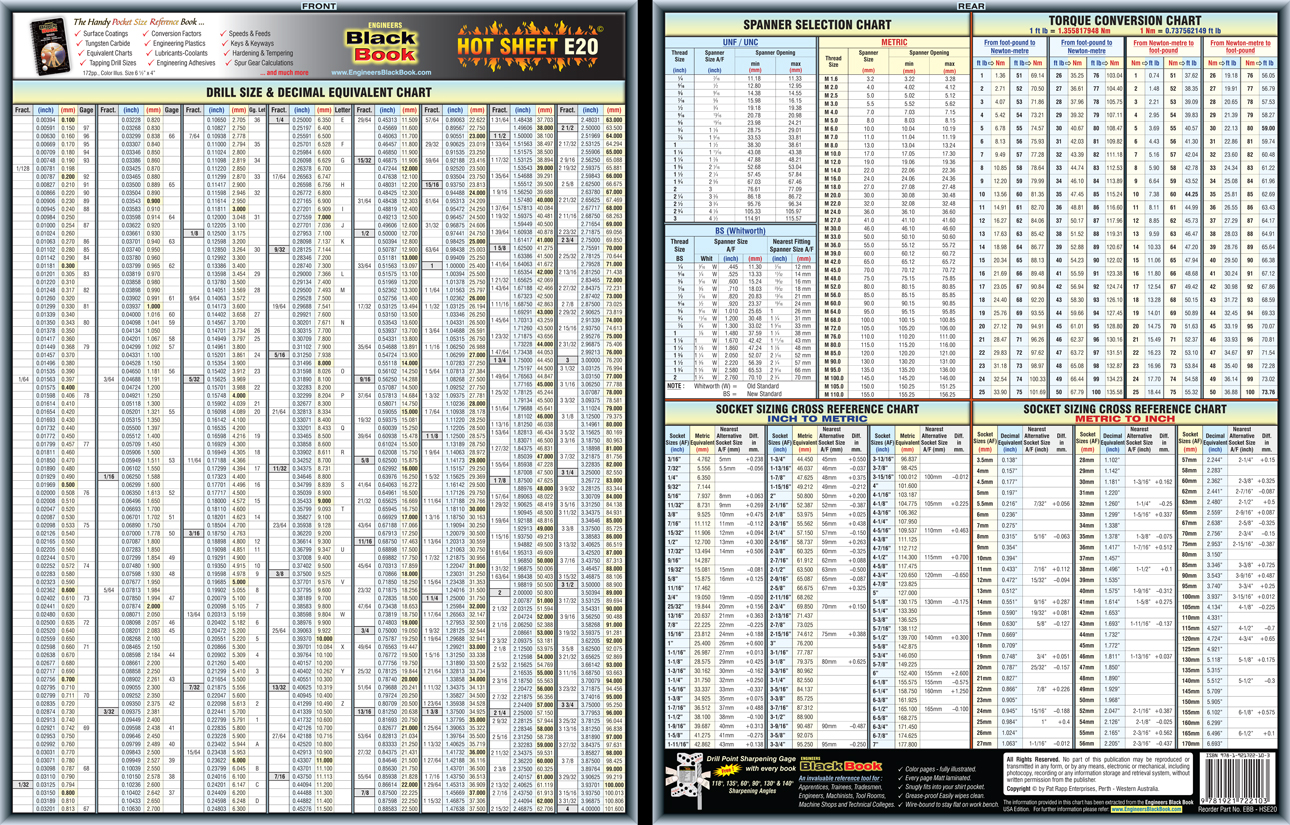

ENGINEERS Black Book The ultimate engineers reference book.  Data sheets, formulae, reference tables, equivalent charts and more. English 44 136 C Engineers Black Book - 2nd Edition 1 Engineers Black Book - 2nd Edition TUNGSTEN CARBIDE TOOLHOLDER IDENTIFICATION (THREADING) SPEEDS AND FEEDS FOR StANDARD CARBiDE DR types of Solid Carbide Drills C 1 6 N Straight Flute Drill Gauge Fract. (inch) (mm).0039.10.150 (inch) 1.092 (mm) 57.0059.0063.0067 1/128 2 1 2020 R Strong construction with 140° drill point angle suitable for hardened & difficult to machine materials.

Data sheets, formulae, reference tables, equivalent charts and more. English 44 136 C Engineers Black Book - 2nd Edition 1 Engineers Black Book - 2nd Edition TUNGSTEN CARBIDE TOOLHOLDER IDENTIFICATION (THREADING) SPEEDS AND FEEDS FOR StANDARD CARBiDE DR types of Solid Carbide Drills C 1 6 N Straight Flute Drill Gauge Fract. (inch) (mm).0039.10.150 (inch) 1.092 (mm) 57.0059.0063.0067 1/128 2 1 2020 R Strong construction with 140° drill point angle suitable for hardened & difficult to machine materials.

Hole depth should not exceed 2 x dia. Engineers Black Book - 2nd Edition DRILL SIZE & DECIMAL EQUIVALENT CHART Slow Spiral Drill - 15°-20° Designed to drill hardened and gummy materials and High-temperature Alloys. Also recommended for Stainless Clamping Insert Clamping C -- Clamp System 16 NUT BOLT 46-51 feed rpm 30-35 feed 69-74 26-31 Shank - h x b Example 2020 = 20 x 20 mm.0201 Internal Toolholder Shank - Diameter d Example 0020 = 20 mm diameter. 7 Engineers Black Book - 2nd Edition COMMON THREAD FORMS USED IN THE ENGINEERING INDUSTRY axis of screw NUT BOLT NUT NUT API BUTTRESS Oil industry for casing.1024.1040 2.642.1043 2.650 No. Of Teeth / Chip Breaker Optional: To Manufacturer’s Discretion (BRITISH STANDARD CYCLE) 30-35 feed 0.18 rpm 730 610 23-28 feed 0.013 0.13 0.15 NOTE: To enhance Hole Quality and Tool Life, the use of copious quantity of coolant is recommended, particularly directed at the drill point to prevent chipping or flaking of the Carbide cutting edge.